Summing up the results of the first year of VMP Astana

A year ago, on August 19, 2022, the grand opening of the VMP Astana plant took place – the only unique production facility in Kazakhstan specializing in innovative protective coatings for metal and concrete with domestic content.

The plant's products, including anti-corrosion coatings, fireproofing materials, and polymer floors, meet high European quality standards and are competitive in the international market. The materials produced at the plant have unique properties: they create a comprehensive protection against corrosion and fire, providing a service life of up to 30 years and a fire-retardant efficiency of up to 150 minutes.

The VMP Astana plant is equipped with high-tech equipment manufactured in South Korea, Italy and Germany. Today, the production process is automated as much as possible. Production capacity of the plant is more than 5 thousand tons per year.

A year ago, the plant's staff numbered 40 people. Today, the plant employs about 100 workers, including highly qualified management, engineering, production, and support staff. The enterprise operates around the clock, without stopping production for a minute.

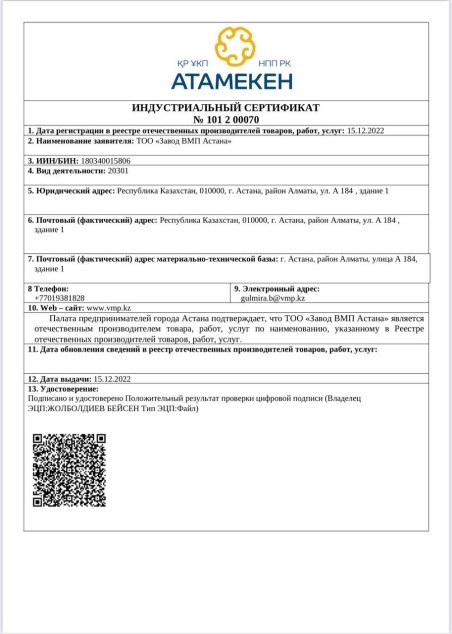

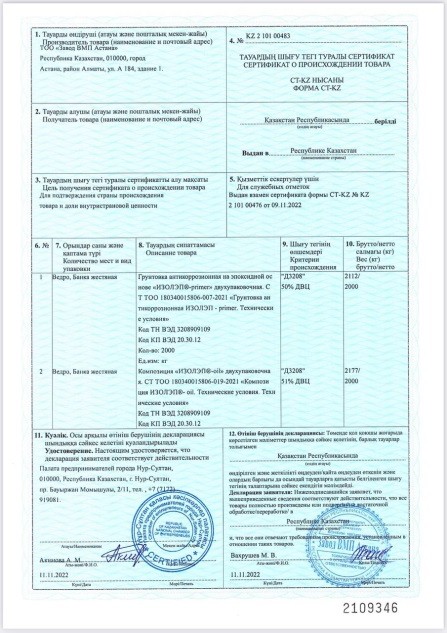

Over the past year, the plant has participated in several exhibitions and conferences, established cooperation with Kazakhstani enterprises and businesses. In addition, VMP Astana has passed a number of certifications and audits, implemented a QMS, received an industrial certificate, as well as certificates CT-KZ for its products.

Today, the plant also aims to become a platform for dialogue between various experts and specialists in the field of metal and concrete protection. So, in the spring, the VMP Astana Plant organized a conference for oil industry companies and design institutes. The conference participants were introduced to effective solutions in the field of protective coatings based on VMP materials. Questions were also raised regarding the existing regulatory documents governing the use of protective coatings, as well as concerning the training and skill enhancement of professionals, technical project support, and audit conduct. A tour of the plant was organized for the guests.

It's worth mentioning that throughout the year, the plant welcomed over 100 specialists and representatives from partner companies for familiarization tours. The guests could personally evaluate the capacities and high production culture at the enterprise, see how the quality control of raw materials and finished products takes place, get acquainted with the capabilities of laboratories and technological developments of the VMP.